Articles

ARTICLES

April 25, 2024

The United States oil and gas industry has reached unprecedented levels of production, setting new records and establishing the country as a preeminent energy superpower. This remarkable achievement is a result of relentless innovation, strategic policy decisions, and the industry's ability to adapt and thrive in a changing global landscape. The Pinnacle of Energy Dominance Recent data from the U.S. Energy Information Administration (EIA) illustrates a significant milestone in domestic oil production. In September 2023, the U.S. shattered previous records by producing over 13 million barrels per day. This feat was not a one-off event but part of an ongoing trend of increasing production, with subsequent months seeing even higher outputs. Technological Innovation and Efficiency A critical factor in this surge is the industry's investment in technology and efficiency. The adoption of hydraulic fracturing and horizontal drilling has unlocked vast reserves in shale formations. Meanwhile, improvements in operational efficiency have allowed for increased production even as the number of active drilling rigs has declined. This demonstrates the industry's capacity to maximize output from existing wells and continuously improve the cost-effectiveness of extraction methods. Regulatory Landscape and Policy Shifts The industry's growth has also been facilitated by a conducive regulatory environment. Key policy changes, such as the lifting of the export ban on U.S. crude oil, have opened up new markets and provided additional momentum. Moreover, the structure of land ownership and regulatory authority, particularly in states like Texas, has allowed for more nimble and responsive governance that supports industry growth. The Broader Impact The implications of America's energy dominance are profound. The U.S. is not only able to meet its own energy needs more reliably but also plays a pivotal role in global energy markets. This position enhances national security, contributes to economic stability, and provides leverage in international diplomacy. Looking Ahead As the industry looks to the future, the focus will remain on sustaining growth through innovation, strategic policy engagement, and maintaining a competitive edge in global markets. The expertise and resilience of those within the oil and gas sector are key to navigating the challenges and opportunities ahead. The United States' achievement in reaching and sustaining record levels of oil and gas production marks a significant chapter in the country's energy narrative. It reflects a collective effort across the industry—from the drillers on the ground to the executives making strategic decisions—to secure America's position as an energy leader on the world stage.

January 2, 2024

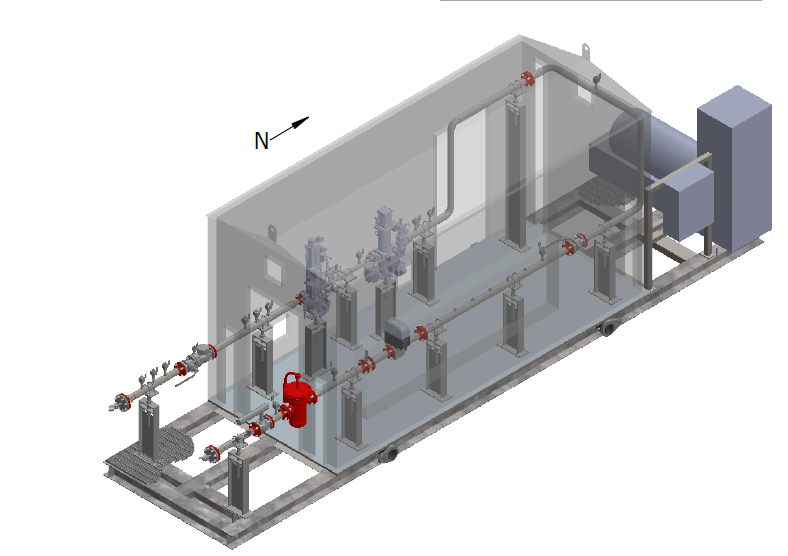

Renewable Natural Gas: Enhancing Sustainability with PEI's Advanced Solutions Renewable Natural Gas (RNG) is redefining sustainable energy, providing an eco-friendly alternative to conventional natural gas. PEI is at the forefront, offering specialized skid-mounted solutions for RNG measurement and regulation, featuring components from leading manufacturers for optimal efficiency and precision. RNG: A Sustainable Energy Alternative RNG is derived from sources like livestock waste, dairy farms, and landfills. Through biogas decomposition and biomethane upgrading processes, RNG is converted into a cleaner fuel, aligning with natural gas standards and significantly reducing carbon emissions. PEI's Expertise in RNG Technology PEI's custom skid solutions for RNG are designed to meet specific customer needs, ensuring compliance with industry standards. Their technology represents a blend of innovation and practicality, offering efficient management of RNG processes. The Environmental Benefits of RNG RNG plays a crucial role in reducing greenhouse gas emissions, contributing to climate change mitigation. Its production from renewable sources like dairy farms represents a significant step towards a more sustainable energy future. The Growth and Potential of RNG The RNG sector is experiencing rapid growth, driven by the increasing demand for cleaner energy sources. Supported by organizations advocating for renewable energy, the industry is poised for further expansion and innovation. RNG's Diverse Applications RNG's versatility is evident in its use across various sectors including heating, electricity generation, and as a vehicle fuel. This adaptability underlines its potential to replace conventional energy sources in multiple applications. PEI's commitment to RNG technology highlights their role in advancing sustainable energy solutions. By focusing on custom, efficient, and environmentally responsible practices, they contribute significantly to the evolving landscape of renewable energy.

November 1, 2023

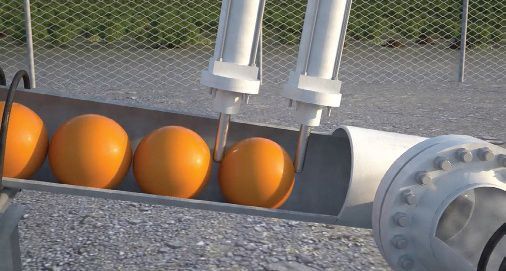

Many years ago spherical pigs were commonly used in natural gas pipelines to remove liquids – mostly water and condensates. The launchers were designed to only handle spherical pigs, using special valves such as the Wheatley Launch Valve and the Fitzpatrick Launch Valve. These resembled a check valve and were designed to release one spherical pig at a time by movement clapper with a lever. Then, with the implementation of Pipeline and Hazardous Materials Safety Administration (PHMSA) requiring that high pressure transmission lines be routinely inspected to prove integrity with inline inspection (ILI) tools, and with the installation of process equipment to remove these liquids, the spherical pigs slowly disappeared from the market. Today, however, with the drilling and development of the shale plays where producers found rich gas – containing large amounts of liquids such as butane, propane and ethane – the need to frequently pig to remove liquids has reappeared. The producers have learned that these rich-gas gathering systems are very profitable, but need to be pigged often – as many as four times a day – to keep production at high levels while capturing these liquids. Another factor that determines the pigging frequency is the amount of liquid being delivered with each pig run, compared to the amount of liquid that could be handled with the liquid separation equipment. If 500 barrels of liquid was delivered with each pig run, and the separation equipment could only handle 500 barrels, it would be necessary to pig the line daily. So, what pigs can be loaded several (10-12) at a time and released automatically on a timed basis or remotely, one at time, several times a day or a week, that can remove liquids? Hence, the reemergence of the spherical pig. Spherical pigs are hollow round balls, most are made from polyurethane, others from rubber products like neoprene. Most are inflatable and equipped with two 180-degree opposed molded-in inflation valves assembly. Today, there are also non-inflatable spheres appearing on the market. These require less pressure and less flow to move through a pipeline because they are not filled with liquid, have a thinner wall and vent holes to equalize pressure. The inflatable spheres must be filled and inflated with a liquid in order to hold their shape when exposed to high external pressure. With the use of an inflation pump the sphere is sized using a sizing ring at the pipe ID or slightly larger. They tend to roll and/or rotate while traversing a pipeline, which prolongs their wear life. Their wiping surface is all that touches the pipe and thus displaces most of the liquid within the pipeline. As a result, the wear life of an inflatable sphere will approach 1,000 miles.

November 1, 2023

Tulsa, Oklahoma – Pipeline Equipment, Inc. (PEI), a leading provider of turnkey custom fabricated solutions, today announced the following additions to its North American Sales Team to meet client demand: Darren Schwarz was hired as Senior Sales Representative. Mr. Schwarz is an expert in Measurement with multiple patents to his name. He will be based in Houston, Texas and joins Ray Brown and Duane Ellis on PEI’s Houston-based team. Energy Equipment, Inc. is a Michigan based Manufacturers Representative that has represented Pipeline Equipment, Inc. for more than a decade. Nelson Technologies, Inc. is a Minnesota based Manufacturers Representative with sales offices in Chicago, Illinois and Des Moines, Iowa. They have been in business for over 30 years and have long-standing relationships in the industry. They will represent Pipeline Equipment in Nebraska, Minnesota, Iowa, Missouri, Illinois, Indiana, Wisconsin. “Our goal is to provide our customers with hands-on expert sales assistance during every phase of the project lifecycle,” said Brent Lollis, Senior Vice President of Sales and Marketing for PEI. PEI’s expansion comes on the heels of several years of significant growth that recently landed the company on Inc. Magazine’s list of the fastest growing private companies in America. The company continues to expand its core business in the oil and natural gas industries while exploring new opportunities in the water, food, extraction and other emerging industries. “The expansion we’re announcing today demonstrates our commitment to providing high quality local service to our customers,” said Lollis. “We will continue to invest in our team as our customers continue to trust us to provide quality equipment, every time.” ABOUT PEI Pipeline Equipment, Inc. was founded in 1995 as a small fabricator of launchers and receivers for customers in Oklahoma and surrounding states. Today, Pipeline Equipment, Inc. provides turnkey custom fabricated solutions to customers worldwide in the oil, natural gas, water, food and other emerging industries. The company is located on 35 acres and has over 150,000 square feet of production space. PEI has in-house Engineering and I&E teams that support the fabrication of launchers, receivers, measurement skids, valve settings, automation and the industry leading TWINLOCK Quick-Opening Closure. PEI also boasts a 30,000 square foot industrial coating facility and one of the only extrusion operations in North America with the ability to produce single and multiple outlet headers using the closed-die forming process. For more information, visit www.pipelineequipment.com CONTACT Brent Lollis Senior Vice President, Sales & Marketing 918-224-4144 877-914-4144 brent@pipelineequipment.com

November 1, 2023

PIPELINE EQUIPMENT, INC. IS THE LARGEST OKLAHOMA MANUFACTURER ON THE 2019 INC. 5000 LIST OF AMERICA'S FASTEST-GROWING PRIVATE COMPANIES TULSA, OKLAHOMA, August 14, 2019 – Pipeline Equipment, Inc., a leading fabricator for the oil and gas industry and the manufacturer of the TWINLOCK Quick Opening Closure, announced it has been named the largest manufacturer in Oklahoma on the annual Inc. 5000 list with three-year revenue growth of 78 Percent. The Inc. 5000 is the most prestigious ranking of the nation’s fastest-growing private companies. The list represents a unique look at the most successful companies within the American economy’s most dynamic segment—its independent small businesses. Microsoft, Dell, Domino’s Pizza, Pandora, Timberland, LinkedIn, Yelp, Zillow, and many other well-known names gained their first national exposure as honorees on the Inc. 5000. “Being included in such a prestigious list is a great honor,” said Jack Lollis, president and founder of PEI. “Being the largest Oklahoma manufacturer on the list in terms of both revenue and number of employees is something we take great pride in. When we started the company, we set out to build a foundation of quality and integrity that would stand the test of time. Recognition like this makes us believe we’re on the right track. To be able to maintain such a high rate of growth over 25 years is very humbling. We would also like to congratulate all of the other honorees.” Not only have the companies on the 2019 Inc. 5000 been very competitive within their markets, but the list as a whole shows staggering growth compared with prior lists. The 2019 Inc. 5000 achieved an astounding three-year average growth of 454 percent, and a median rate of 157 percent. The Inc. 5000’s aggregate revenue was $237.7 billion in 2018, accounting for 1,216,308 jobs over the past three years. “The companies on this year’s Inc. 5000 have followed so many different paths to success,” says Inc. editor in chief James Ledbetter. “There’s no single course you can follow or investment you can take that will guarantee this kind of spectacular growth. But what they have in common is persistence and seizing opportunities.” The annual Inc. 5000 event honoring the companies on the list will be held October 10 to 12, 2019, at the JW Marriott Desert Ridge Resort and Spa in Phoenix, Arizona.

November 1, 2023

DESIGN, SELECTION When designing a quick-opening closure, one must follow the appropriate design code for the given application. Pig launcher and receiver closures are normally designed to pipeline design codes ASME B31.4 for liquid pipelines or ASME B31.8 for gas pipelines. Quick-opening closures installed on pressure vessels are normally designed to ASME Section VIII, Division 1. These codes basically dictate the formula for calculating material thicknesses and allowable material types. The quick-acting design is determined, proven and tested by the supplier. However, certain design safety features are required by code within ASME Section VIII, Division 1, paragraph UG-35b: Designed such that a failure of a single locking component will not cause closure to leak or fail under pressure. Equipped with a pressure-warning device to alert the operator to the existence of internal pressure. There are 8-10 major closure manufacturers in the United States. Although the design features will vary with each supplier, there are basically three prominent designs commonly used: Threaded type – A two piece closure with door and hub, using an acme-type thread for holding the door to hub, using an O-ring seal. Door latch type – A two-piece closure with door and hub, using a latch-type mechanism for latching the door to hub, using an O-Ring seal. Clamp ring type – A three-piece closure with door, hub, and clamp ring. The clamp ring is used to holding the door and hub, using an O-Ring seal. The door latch type and clamp ring type are preferred, particularly in the larger sizes, for ease of operation. Some suppliers also offer a flanged closure that can simply be bolted on to a mating flange installed on the pressure vessel.

November 1, 2023

According to Hopkins, the magnet also serves as a trouble-shooting tool. “The magnet can identify problems faster than oil analyses. There is always going to be some metal on the magnet due to normal wear, but a 1- or 2-in. metallic ‘hair ball’ means that something is not right,” said Hopkins. “By the time oil analysis comes back showing there is iron in the oil, for example, the unit may already have gone down. If the mechanic finds metal on the magnet during routine servicing, he can find out where it is coming from right away and potentially avoid unplanned downtime.” The centrifuge is a side-stream filtration system designed to remove carbon, dirt, metal, and other solids elements to 0.005 microns. “Oil pressure drives the centrifuge, meaning no air, gas, or electricity is needed to power it,” said Hopkins. “The centrifuge is designed to extend engine life by removing solids — even the carbon from blow-by from the rings that end up solids — in the bottom of the oil pan and darkens your oil leading to the bearings, cams, rings, and valves.” Each Duration Filtration System is designed to meet the requirements of the specific application. “Every location is its own beast,” said Hopkins. “We will design filter elements based on their needs for that particular application. We work with the customer, we analyze their product, and we find out what particulate size solids are in their systems. Once we know what particulate sizes we are dealing with, we design a system that meets their specific needs. And, they only purchase our system According to Hopkins, the idea is to have one element for everything. “If an operator has 60 engines in a plant, they will each use the same Duration filter element regardless of the engine manufacturer. If they have any application and are running a 50-micron filtration, it’s also the same element. We make filtration simple by designing our filter elements to fit any of our housings. Spares are based on what is needed at the facility. They may only need four spares for 60 engines. When a mechanic comes in to do planned maintenance, they pull the filter element and put in the spare. They take the filter element they just pulled and clean it, and now that becomes the spare. It doesn’t matter if that element went to the engine or the amine or any other process, it is clean,” said Hopkins.“

November 1, 2023

Pipeline Equipment, Inc. is pleased to announce the following additions to its sales organization: V&P Sales Mike Orgeron - morgeron@vandpsales.com Territories: Louisiana Western Gas Technologies Michael T. Legittino - mtl@westerngastech.com Vincent O'Conner - vpo@westerngastech.com Territories: Northern California - North of San Luis Obispo, Kern, San Bernadino Counties, AK, AZ, HI, ID, NV, UT, OR, WA For more information visit the Find a Rep section of this site.

November 1, 2023

PEI INTRODUCES QUICK OPENING CLOSURE Pipeline Equipment, Inc. introduces the TWINLOCK quick opening closure. Safe and easy to operate, it may be used in a broad range of applications. The closure can be operated by one man without the use of tools. The integration of locking segments, locking mechanism and door handle into the door provides a compact, efficient design. The door opens with only a quarter-turn of the handle. The o-ring seat area is recessed to protect the seat during operation. The safe operation of the closure is ensured by a "twin lock." The closure cannot be opened without the removal of the pressure alert valve and the movement of the safety lock. For more information, please call 918-224-4144, or click here to download a PDF brochure.

August 8, 2022

Tulsa, OK — August 1, 2023 — Pipeline Equipment, Inc., a premier fabricator of products for the Oil & Gas industry, is delighted to announce the appointment of two distinguished professionals, Tiffany Bailey and Steve Calvin, to key leadership positions. Their extensive experience and expertise are expected to drive the company's growth and operational excellence to new heights. Tiffany Bailey - Chief Financial Officer (CFO) Tiffany Bailey joins Pipeline Equipment, Inc. as the Chief Financial Officer (CFO) with over 20 years of experience in corporate and public accounting, financial reporting, and internal audit. As a Certified Public Accountant (CPA), Certified Fraud Examiner (CFE), and with her Certification in Risk Management (CRMA), Tiffany brings a wealth of financial acumen and expertise to the company. In her previous financial leadership positions within Fortune 500 companies, Tiffany played a pivotal role in overseeing the accounting and business functions for two large publicly traded oil and gas companies. Her leadership in assessing control processes, implementing best practices, and fostering financial transparency has been instrumental in enhancing financial performance. Steve Calvin - Operations Manager Steve Calvin, a seasoned professional with over two decades of experience in operations and management, assumes the position of Operations Manager at Pipeline Equipment, Inc. With a track record of optimizing efficiency and leading cross-functional teams, Steve will oversee engineering and drafting, estimating, purchasing, shipping and receiving, and production. In his previous roles, Steve demonstrated outstanding leadership, implementing Lean principles, and achieving remarkable operational milestones. He consistently fostered high-performance teams and maintained strong relationships with customers and stakeholders.

All Rights Reserved | Pipeline Equipment, Inc. | Site by Creative State

© 2025