Pipeline Equipment, Inc. is the Largest Oklahoma Manufacturer on the 2019 Inc. 5000 List of America's Fastest-Growing Private Companies

PIPELINE EQUIPMENT, INC. IS THE LARGEST OKLAHOMA MANUFACTURER ON THE 2019 INC. 5000 LIST OF AMERICA'S FASTEST-GROWING PRIVATE COMPANIES

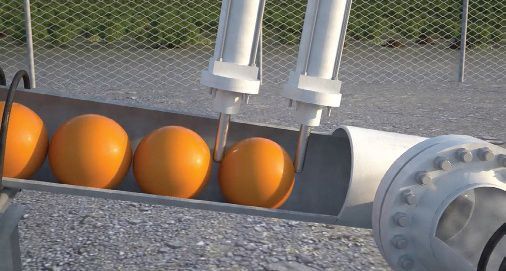

TULSA, OKLAHOMA, August 14, 2019 – Pipeline Equipment, Inc., a leading fabricator for the oil and gas industry and the manufacturer of the TWINLOCK Quick Opening Closure, announced it has been named the largest manufacturer in Oklahoma on the annual Inc. 5000 list with three-year revenue growth of 78 Percent. The Inc. 5000 is the most prestigious ranking of the nation’s fastest-growing private companies. The list represents a unique look at the most successful companies within the American economy’s most dynamic segment—its independent small businesses. Microsoft, Dell, Domino’s Pizza, Pandora, Timberland, LinkedIn, Yelp, Zillow, and many other well-known names gained their first national exposure as honorees on the Inc. 5000.

“Being included in such a prestigious list is a great honor,” said Jack Lollis, president and founder of PEI. “Being the largest Oklahoma manufacturer on the list in terms of both revenue and number of employees is something we take great pride in. When we started the company, we set out to build a foundation of quality and integrity that would stand the test of time. Recognition like this makes us believe we’re on the right track. To be able to maintain such a high rate of growth over 25 years is very humbling. We would also like to congratulate all of the other honorees.”

Not only have the companies on the 2019 Inc. 5000 been very competitive within their markets, but the list as a whole shows staggering growth compared with prior lists. The 2019 Inc. 5000 achieved an astounding three-year average growth of 454 percent, and a median rate of 157 percent.

The Inc. 5000’s aggregate revenue was $237.7 billion in 2018, accounting for 1,216,308 jobs over the past three years.

“The companies on this year’s Inc. 5000 have followed so many different paths to success,” says Inc. editor in chief James Ledbetter. “There’s no single course you can follow or investment you can take that will guarantee this kind of spectacular growth. But what they have in common is persistence and seizing opportunities.”

The annual Inc. 5000 event honoring the companies on the list will be held October 10 to 12, 2019, at the JW Marriott Desert Ridge Resort and Spa in Phoenix, Arizona.

MEDIA CONTACT

Brent Lollis, SVP – Sales & Marketing

Pipeline Equipment, Inc.

918-224-4144

brent@pipelineequipment.com

ABOUT PIPELINE EQUIPMENT, INC.

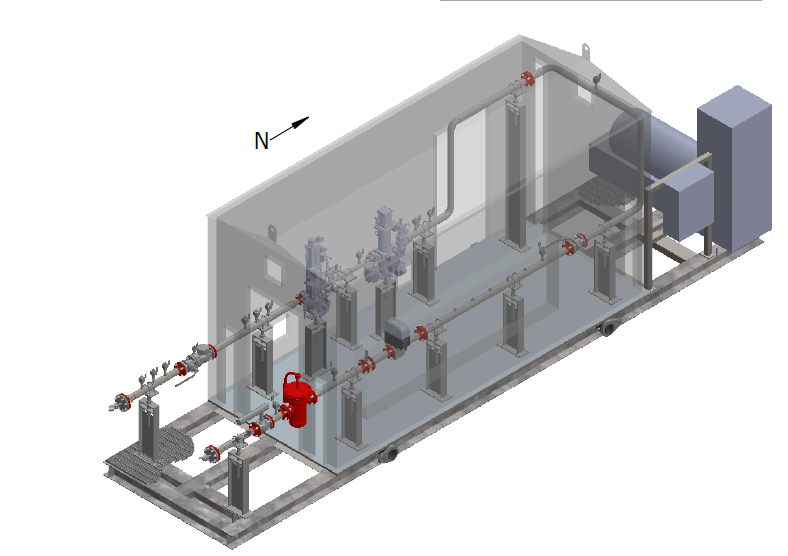

In 1995, after spending more than 25 years in the Oil & Gas Industry, PEI’s founder set out to build a company with integrity and a dedication to quality and customer service. Today PEI has over 150 employees in four divisions: Fabrication, TWINLOCK Closures, Extrusion and Industrial Coating. For more information, call 918-224-4144 or visit www.pipelineequipment.com

ABOUT INC. AND THE INC. 5000

Methodology

The 2019 Inc. 5000 is ranked according to percentage revenue growth when comparing 2015 and 2018. To qualify, companies must have been founded and generating revenue by March 31, 2015. They had to be U.S.-based, privately held, for profit, and independent—not subsidiaries or divisions of other companies—as of December 31, 2018. (Since then, a number of companies on the list have gone public or been acquired.) The minimum revenue required for 2015 is $100,000; the minimum for 2018 is $2 million. As always, Inc. reserves the right to decline applicants for subjective reasons. Companies on the Inc. 500 are featured in Inc.’s September issue. They represent the top tier of the Inc. 5000, which can be found at http://www.inc.com/inc5000.

About Inc. Media

Founded in 1979 and acquired in 2005 by Mansueto Ventures, Inc. is the only major brand dedicated exclusively to owners and managers of growing private companies, with the aim to deliver real solutions for today’s innovative company builders. Inc. took home the National Magazine Award for General Excellence in both 2014 and 2012. The total monthly audience reach for the brand has been growing significantly, from 2,000,000 in 2010 to more than 20,000,000 today. For more information, visit www.inc.com.

The Inc. 5000 is a list of the fastest-growing private companies in the nation. Started in 1982, this prestigious list has become the hallmark of entrepreneurial success. The Inc. 5000 Conference & Awards Ceremony is an annual event that celebrates the remarkable achievements of these companies. The event also offers informative workshops, celebrated keynote speakers, and evening functions.

For more information on Inc. and the Inc. 5000 Conference, visit http://conference.inc.com

PEI Articles

All Rights Reserved | Pipeline Equipment, Inc. | Site by Creative State