Correct Pigs, Procedures for Hydrostatic Testing of New Pipelines

By Larry Payne, Business Development Executive, Pipeline Equipment, Inc.

Laying a cross-country pipeline is expensive. Many hours of engineering and planning must meet certain standards and regulations and receive federal government approval before starting construction. It costs approximately $100,000 per diameterinch-mile to build a pipeline in a reasonable lay area. This number can easily triple in marsh lands, hills, mountains and rocky terrain. In those areas it could cost about $20 million to lay 100 miles (161 km) of 20-inch pipe.

After taking several years to achieve all this, construction begins and the pipeline is laid in sections, with each one required to be hydrostatic-tested to prove the pipeline will withstand the operating pressure with a safety factor applied, and without leaking. These test sections will vary in length, depending on the elevation changes within a given test section to allow a near uniform test pressure throughout its length. Typically, the more level the terrain, the longer the test section.

Once the test sections are complete and ready for hydrotesting, the line must be cleaned of construction debris, filled with test water, dewatered, and dried to a given specification before it is tied into the other sections and put into service. This process is accomplished using pipeline pigs propelled with water pumps and high-volume air compressors. This can be a time-consuming and expensive process.

This article will focus on the best type of pigs to be used for the given new construction applications. However, hydrotesting existing pipeline is a method allowed by the Pipeline and Hazardous Materials Safety Administration (PHMSA) to prove pipeline integrity, and the same pigs and procedures should be considered.

Cleaning

The first pigging application is to clean the line of construction debris, which includes dirt, rocks and used welding rods, among other items. Normally with the high-yield, thin-wall pipe being installed today, it is not uncommon to find 2 to 4 inches (0.051 to 0.102 mm) of out-of-round pipe after it has been laid and back filled. This out of roundness will usually go away after pressure testing or when the line is placed in service.

When selecting the cleaning pig to remove the construction debris, consider a disc/cup pig with brushes to remove the mill scale or surface rust. Select one capable of negotiating the above-mentioned reductions. It is always prudent to have a tracking transmitter on the first pig through in case it becomes stuck. Large, portable, high-volume air compressors are used to propel these pigs through the line.

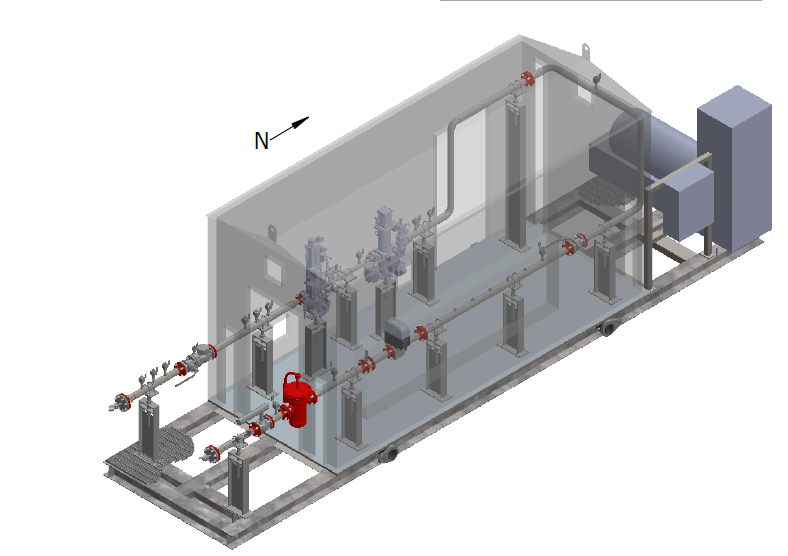

Each test section should have a portable pig launcher and receiver installed. If you are going to make multiple pig runs, which is likely, this reduces the cost of having to cut and re-weld pipe caps on test headers for each run.

Do not run the pig into open-ended pipe. This is very dangerous and can result in serious damage. If fact, if the line can be pre-pressured (packed) to 50 to 70 psig (3.45 to 4.83 bar), the pig speed can be controlled by restricting the air flow at the receiver; the results will then be much better and safer. Dependent on the size of pig, the pressure needed to propel it is relatively low (10 to 40 psig [0.69 to 2.76 bar]).

The problem occurs when the pig is moving at 25 psi (1.72 bar) and enters a heavy wall fitting or pipe, needing another 10 psi. The pig may be 5 to 10 miles (8 to 16 km) from the launch site and the compressors need to compress that length of pipe another 10 psi. When the pig finally clears the restriction, the stored energy behind it may accelerate it at speeds upward of 50 mph (80 km/h).

Pigs do not do well at those velocities and you certainly do not want one entering the receiver at that speed. You should hold a back pressure at the receiver to reduce these speed excursions. It also is good practice to inject 10 to 15 barrels of wash water ahead

of the cleaning pig. This will allow more construction debris to be removed and should leave the line cleaner with less deferential pressure to move the pig.

Now the construction debris has been removed through a minimum of two cleaning runs. The second run confirms the line is clean from the construction debris.

Line Fill and Dewatering

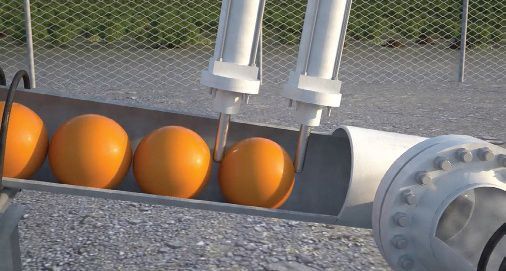

The most critical phase of a hydrotest is getting a good line fill. Select a good seal pig that displaces the air with a solid column of water. Pig speed will not be as critical because it will only move as fast as the water being pumped behind it – usually 1 to 3 mph (1.6 to 4.8 km/h). Again, pig type is critical.

The pig should have four conical cups, which maintain a good seal because the driving pressure exerts an outer pressure on the sealing surface and the cups are flexible enough to maintain a seal in out-of-round pipe or dents and buckles. These conical-cupped pigs will traverse reductions of 20% to 30% and maintain a good seal when traversing the line. The person conducting the hydrotest will immediately know if they have a good line fill from the sound of the pressure pump and the rise in the line pressure.

Once the line has been tested, it is ready to be dewatered and dried. The same pig type used for line fill should be used to dewater. If fact, run it several times; the intent is to remove all standing water, leaving only a wet wall. This will greatly reduce the number of drying runs with foam pigs.

I strongly recommend a geometry tool inspection run for every newly constructed pipeline. Often called a caliper pig, it will find any dents or buckles that may have occurred during construction. These irregularities can now be sized, located and fixed.

Bare swab foam pigs are considered the drying pig of choice. These pigs will absorb the water due to the fact they are open-cell foam, like a sponge. They are run using hot, dry, compressed air to propel them through the line. They require very little pressure to move them – 3 to 5 psi (0.2 to 0.3 bar) – depending on size.

The line dryness (dew point) may be measured at the launch and receive sites, but the receive site measurement will determine the line dryness via penetration of liquid within the outer periphery of the foam pig.

These bare swab foam pigs normally have a density of 1 to 2 pounds (0.5 to 0.9 kg), i.e., 1 cubic foot (0.03 m3) weighs 1 to 2 pounds. I recommend medium density (4 to 5 pounds [1.8 to 2.3 kg]) for the first foam pigs. These denser pigs tend to squeeze more water from the pipe wall.

In Service

Once the dew point is achieved in this section, it is time to move to the next section. This same process will be used until all sections have been successfully cleaned, tested and tied together. Once this process is complete, it is time to fill the line with product and place it into the service for which it was intended.

When filling the line for service and displacing the air with product, again use a multicupped pig, depending on the product. Consider using two pigs with a nitrogen batch between them.

In summary, building a new cross-country pipeline is a large investment for pipeline companies. Pipeline contractors are usually the ones making the decision when selecting the methods and pig types for these new construction applications.

Not only will the right selection save the contractor time and money, it assures the owner that they are getting a pipeline properly prepared for the service for which it was intended.

PEI Articles