By Larry D. Payne, Business Development, Pipeline Equipment and Kyle Corriveau, Project Engineer, Pipeline Equipment, Inc., Tulsa OK

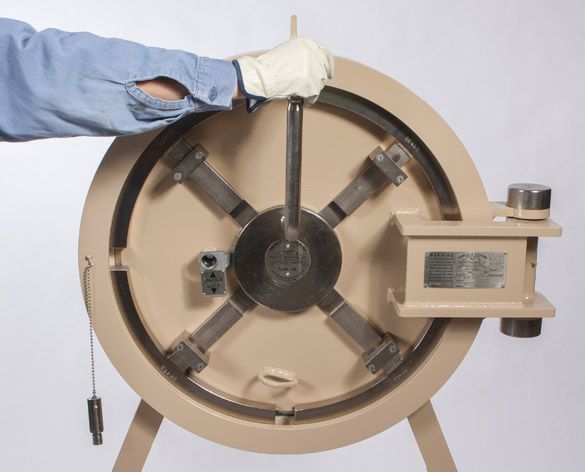

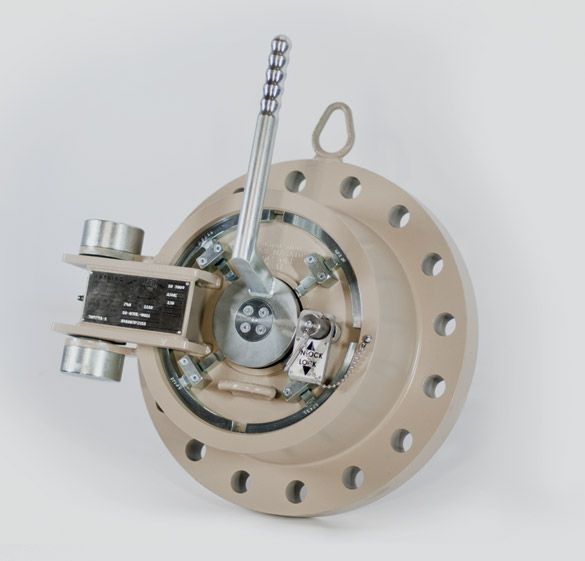

The common definition of a closure is a pressure-containing component used to blank off an opening nozzle on a vessel or end of pipeline. Under this definition, a closure could be:

Weld cap (flat, ellipsoidal, spherical, conical)

Bolted blind flange

Quick opening closure

As defined by ASME B31.4 and ASME B31.8 a quick-opening closure is a pressure- containing component used for repeated access to the interior of a piping system.

As defined by ASME VIII-1 UG-35.2 (a) (1): Quick-actuating or quick-opening closures are those that permit substantially faster access to the contents space of a pressure vessel than would be expected with a standard bolted flange connection.

PEI’s expanded definition is “a quick opening closure allows the operator quick, easy, and safe access to the interior of a pressure vessel.”

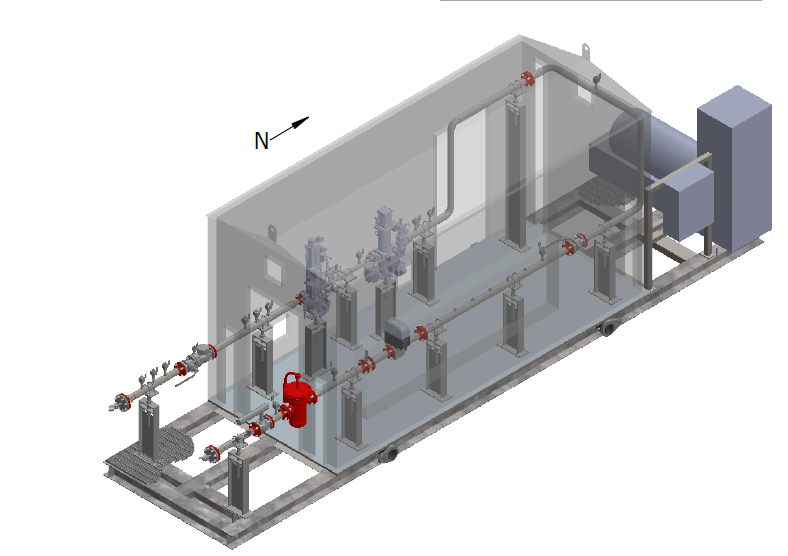

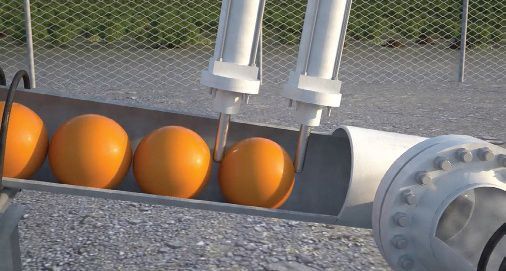

It is estimated that there are over 250,000 quick-opening closures in service on any given day within the United States. Quick opening closures are primarily installed on pig launchers and receivers, pressure vessels such as filter units, and blowdowns on vertical vent stacks.