Duration Filtration System reached 25 years in the field in 2017. To celebrate the milestone, the company has introduced a 25-year warranty on its filter elements. Developed by John Hopkins Unlimited Inc., the Duration Filtration System is a solids filtration system with no disposable elements.

Headquartered in San Antonio, Texas, USA, John Hopkins Unlimited manufactures the Duration Filtration System for global distribution. “In the beginning, we started with oil filtration for natural gas engines,” said John Hopkins, president and founder of John Hopkins Unlimited Inc. “After years of real-world testing, we found that the make and model of the engine didn’t matter. It works on high-speed and low-speed engines – Caterpillar, Clark, Cooper, Delaval, Jenbacher, Waukesha, and White Superior.

We have installed the Duration System onto engines running in the field in all conditions, in all operating environments, and the same filter element works across the board. Our filtration technology has not changed since day one. The only thing that has changed since the first filter went into the field 25 years ago is that today we offer 2- and 3-stage filtration systems. We have filtration systems running in engine oil, hot oil, amine, glycol, saltwater disposal, inlet gas, and water jacket applications. The Duration Filtration System can replace 75% of an end user’s solids filtration needs, with no disposable elements whatsoever.”

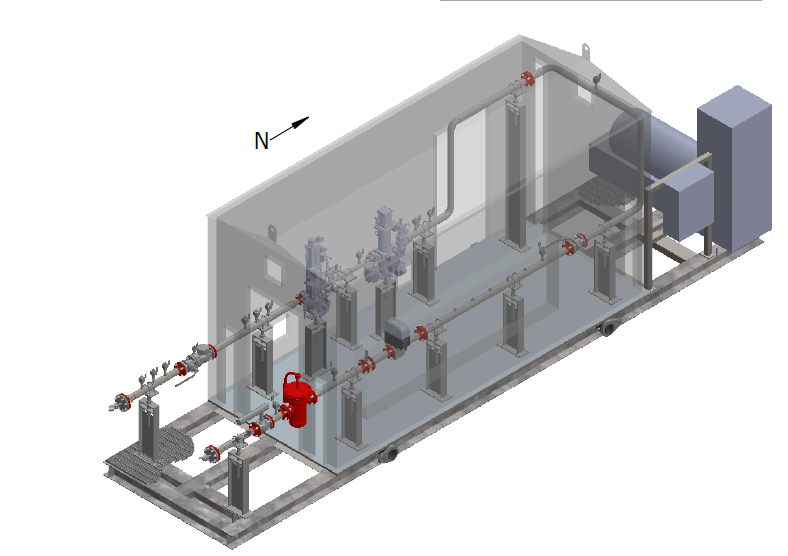

The Duration Filtration System is comprised of three components: a full-flow stainless steel bag-type filter element, a magnet, and a centrifuge. The 3-stage system incorporates each component and is typically used in engine applications. The 2-stage system uses only the filter element and magnet and is typically used in process applications such as inlet gas, amine, water jacket, glycol, and saltwater disposal. The housing for the filter element can be designed to meet all required ASME codes for the application into which the system is being installed.

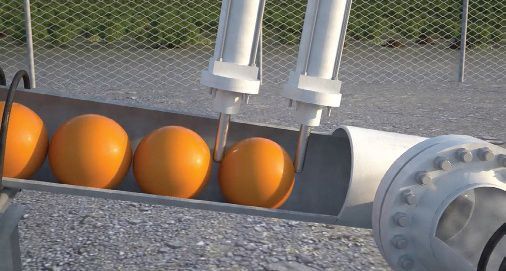

The filter element is a bag-type filter made of 316L stain-less steel. The filter element is designed to replace disposable filters such as cartridge filters, paper filters, sock-type filters, wire mesh systems, and others. Filtration properties are available from 10 microns to as large as needed and differential pressures as high as 250 DP.

“The advantage of bag-type filter elements versus a cartridge filter element is that the bag-type fillter flows inside-out, containing all solid contaminates within the element itself. With cartridge fllters, the flow is outside-in. When oil or process fluid is drained to remove the filter, contaminates that did not impregnate on the filter fall to the bottom of the filter housing,” said Hopkins. “The reality is, not everyone is as diligent as they should be when it comes to cleaning or purging the bottom of the housing before the new filter element is put in. When the unit is restarted, all the contaminates are immediately drawn back into the new filter element, shorting its lifespan. With the Duration Filtration System, the operator pulls the filter element and all the contaminates remain inside the filter element. No purging is required, no drums to haul filters in, and no draining filters before disposal and packing drums to dispose. The filter element is cleaned with a pressure washer and returned to service. There is nothing to dispose of.”

The magnet is a stainless steel tube magnet that pulls metal particles from the system, thereby extending the life of the filter element. “The biggest dump of metal is during startup of a new engine or rebuilt overhauled engine, when the rings and liners break in,” said Hopkins. “The metal from these components is very fine. With traditional filtration systems this metal collects onto the filter, shortening its lifespan. With the Duration System, the magnet collects these metallic particles, extending the operating life of the filter. With our system, the filter element and magnet are removed and cleaned using a pressure washer and returned to service. With a disposable filtration system, the operator incurs all the costs associated with purchasing, freight in, storing, removing, draining, and disposing of the filters."