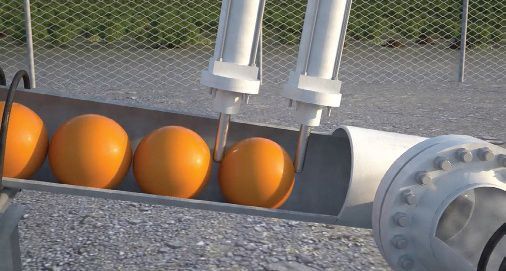

Having been engaged for many years in running pigs, inspecting sites, designing and building pig traps worldwide, we have seen a variety of applications, locations and product types, along with a wide array of designs – some good, some bad. We believe natural gas and liquid pig launchers and receivers should differ in

design but share some common features. Certain applications require specially designed units. For example:

- Offshore sites where space is limited, and vertical units are more suitable.

- Wet gas gathering systems when lines may need to be pigged several times a day or week to remove liquids. Automating these units saves manpower, reduces gas releases, cuts valves maintenance cost, and addresses safety concerns.

1) Purpose of pigging

Pipelines are normally pigged for one or more of the following reasons:

- Cleaning: To improve flow efficiency or reduce internal corrosion.

- Displacement: To displace the line contents.

- Batching: To separate different products within an operating pipeline.

- Inline inspection: To perform an internal inspection with an inline inspection (ILI) tool for integrity purposes.

One must establish a need to pig a pipeline before investing in the installation and operation of a pig launcher and receiver.

2) Size

A typical designation for pig launchers/receivers would be:

- 10-inch by 12-inch 300# pig launcher or pig launch system

- This would indicate a launcher for a 10-inch pipeline with a 12-inch oversize barrel that allows the operator to slide the pig into launch position. The maximum operating pressure could be 740 psi. The word “system” generally implies that all valves and associated piping are included.

- 20-inch by 24-inch 600# pig receiver or pig receive system

- This would indicate a receiver for a 20-inch pipeline with a 24-inch oversize barrel and could have a maximum operating pressure of 1480 psi.

We recommend the oversize barrel be one size larger than the pipe size for pipe diameters up to 10-inch (i.e., 6-by-8, 10-by-12). On any pipe size of 12 inches or larger, the barrel size should be at least two pipe sizes larger (such as 16-by-20, 20-by-24). An odd sized barrel would be a reason to increase the barrel size to the next readily available pipe size, such as 24-by-30.

3) Length

The launcher or receiver length is determined by the type of pigs used. Today, most launchers and receivers are designed to accommodate the length of an ILI tool. A unit long enough for an ILI tool is certainly a sufficient length for cleaning, batching, and displacement pigs. The ILI tools have gotten longer due to multi-data set technologies. Each section of an ILI tool collects different types of data, which provides detailed information on the integrity of the pipeline. As a rule of thumb, we consider an ILI tool to be 15 feet long on average. Therefore, the oversize barrel should be slightly longer than 15 feet and the receiver should have a length of line size pipe to ensure the ILI tool has cleared the mainline trap valve. A receiver designed to handle an ILI tool will need to be over 30 feet long. The launcher can be shorter due to the line size portion being 8 feet to 10 feet shorter. If the pipeline is not to be designed for ILI tools, the length of the launcher and receiver can be reduced accordingly. Cleaning, batching, and displacement pigs are approximately two pipe diameters in length. Receivers should be designed to be long enough to hold at least two pigs.

4) Pressure rating

Launchers and receivers are normally designated to a flange rating of 300#, 600#, 900#, etc. However, the actual working pressure and test pressure are determined by the operating conditions and design code of the pipeline system. Most operators will designate the Max Operating Pressure (MOP) and set a pressure rating to which the launchers and receivers are to be designed. We recommend the design factor be at least 0.5 since launchers and receivers see multiple pressure cycles throughout their lifetime that the pipeline does not experience.

5) Launcher design vs. receiver design

We have already discussed why the launcher is generally shorter than the receiver. The launcher and receiver have the same number of nozzles but differ in location for a variety of reasons. The launcher should have a “kicker line” located near the closure, allowing flow to be directed behind the pig for a successful launch. This “kicker line” is normally sized one-third to one-half the size of the pipeline. A 12-inch pipeline would have a 4-inch to 6-inch kicker line. For a 12-inch line, we recommend a 6-inch kicker on a natural gas pipeline and a 4-inch kicker on a liquid pipeline.

On the receiver, we call this line the “receiver bypass line.” This line should be located near the reducer entering the oversize barrel. This location allows the flow to exit the receiver without the pig interrupting the flow, space for the pig to come to rest in the oversize barrel without striking the closure door and easy retrieval.

Both launchers and receivers should have a vertical vent line above head height located near the closure and a pressure gauge connection near the closure allowing the operator to view the line pressure within the unit. Liquid units should have a drain system that allows the liquid to drain into a sump tank. This drain system on the receiver should have a minimum of two drain connections in front of and behind where the pig comes to rest. This prevents the drains from being blocked by the pig and allows the entire barrel to be drained. These vents and drains should be appropriately sized to allow for the venting and draining to be achieved in a reasonable timeframe.

It is not ideal to drain a 36-inch by 40-inch receiver through a 2-inch drain. The other crucial nozzles on both the launcher and receiver are the equalization lines. These lines allow the pressure and product to be filled, vented and equalized on either side of the pig. The loading of long and heavy ILI tools can be difficult because the tools have flexible joints with several sections. These tools can be loaded using a tray or a system of nozzles and cables to assist with loading.

Pig indicators are critical in determining if the pig has been launched or received and must be installed in the correct position. The pig indicator on the launcher should not be installed on the launch barrel but downstream of the mainline bypass tee. The pig indicator on the receiver should be installed on the line size pipe near the reducer on the receiver barrel. Pig indicators are a critical component; we recommend that two be installed at each location for redundancy, should one fail.

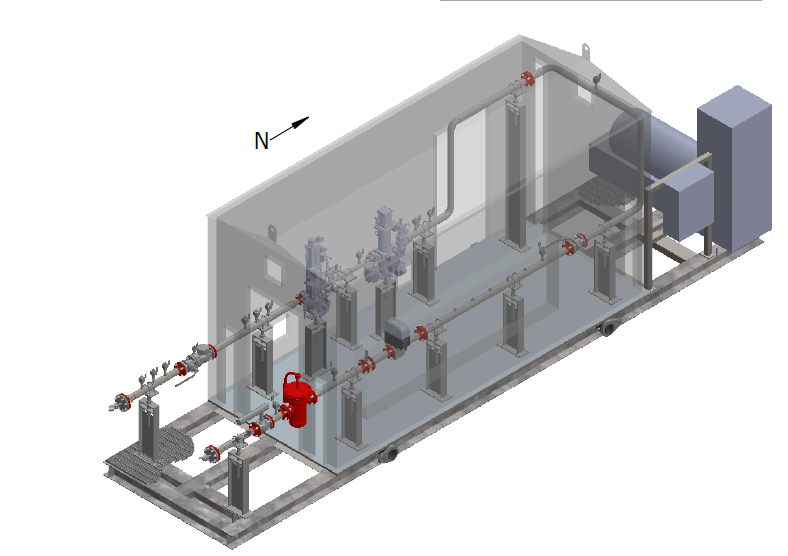

6) Launcher/receiver systems vs. launcher/receiver barrels

The term “system” indicates the unit includes all valves and associated piping. Systems are normally skid mounted, and a completed pigging system requires two major field tie-ins to put it in service. The system is hydro-tested as a complete unit and functionally tested prior to delivery. The site is usually prepared by pouring concrete piers to support the skid weight, then set into position, then bolt connected to the inlet and outlet. This saves a tremendous amount of field installation cost. This also allows for easy access to all the major components for future maintenance needs. A launcher/receiver barrel does not include the valves, piping and skid mounted assembly, which must be assembled, fabricated and tested in the field. Complete pigging systems will save money in the short- and long-term and, if necessary, can be relocated.

7) Product type

Gas launchers and receivers differ from liquid launchers and receivers for some of the same reasons. The primary differences are:

- Design Code (ASME B31.8 Gas vs. ASME B31.4 Liquid)

- Drains and sump tanks are required on liquid launchers and receivers and may also be needed on gas receivers when handling liquids.

When pig launchers and receivers are designed correctly, the benefits you receive are:

- The right design has safety features that eliminate accidents.

- The right design reduces operation and field installation cost.

- The right design eases the launching and receiving process.

- The right design allows for consistency in launching and receiving procedures and operator qualifications.

The right design assures the unit complies with applicable codes and standards.